Product Introduction:

This series of products is used for surface processing of engine valve lock clamping grooves, necks, disk conical surfaces, disk outer circles, disk end surfaces, and rod end surfaces, as well as multi-part combined grinding processing.

Suitable for processing ordinary alloy steels and heat-resistant alloy steels such as 40Cr, 4Cr9si2, 4Cr10si2M, 21-4N, 23-8N, and NCF751 (nickel-based alloy steel).

Technical Note:

The maximum working line speed of this product can reach 180m/s, which is slow feed forming and grinding. The grinding wheel and workpiece have a large contact area and a high speed ratio, which can achieve high material removal rate, greatly improve processing efficiency and reduce processing costs, and maintain the shape of the grinding wheel well during use without any need for trimming.

The contour accuracy of the machining workpiece can reach 0.005mm, and the grinding wheel matrix can be reused.

Product Advantages:

● Designed specifically for wear-prone areas, greatly improving the service life of the grinding wheel.

● High-precision shape

● Grinding wheel stabilizes Hezhong technology

● Long life of the grinding wheel

● Replacing can be repeated several times

● Multi-layer electroplating process can be used in more complex shapes

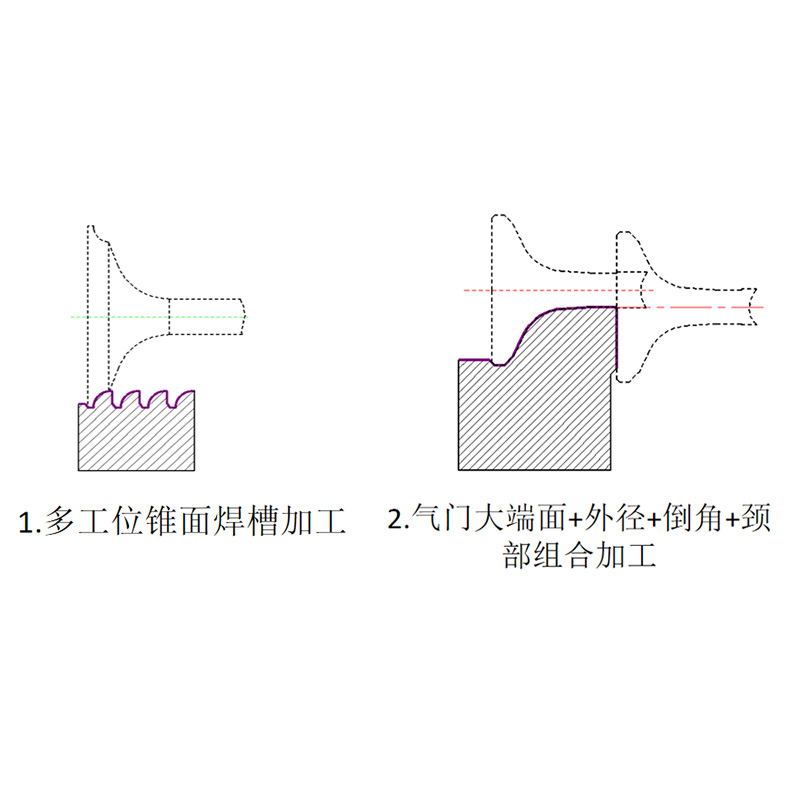

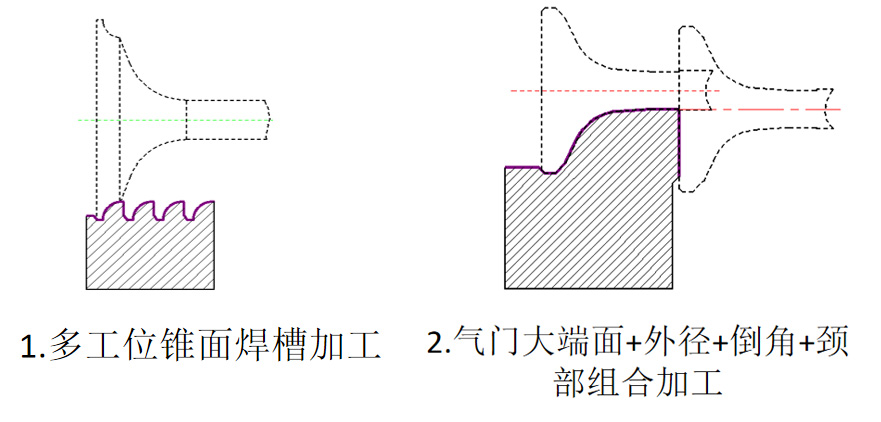

| Processing parts | Processing diagram | Specifications D*T/t*H*W | Linear speed | Workpiece roughness |

| Surface groove | 1. Multi-station cone welding groove processing diagram grinding wheel | 380*(18-35)*Φ160 | 80-150 | RZ10 |

| Large end face Outer diameter Chamfered neck | 2. Large end face of valve, outer diameter, chamfer, neck combination processing grinding wheel diagram | 500*(20-45)*Φ203.2 | 150-180 | RZ10 |

English

English 中文简体

中文简体 русский

русский Español

Español