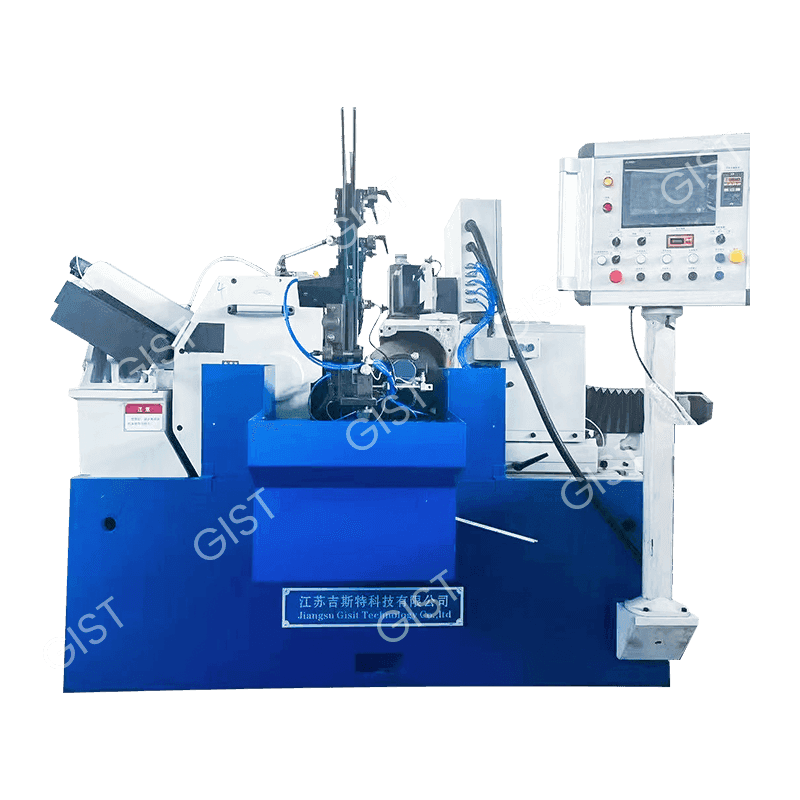

Main parameters of the machine tool

| Maximum machining length | Total valve length 200mm | ||

| Maximum machining disk diameter | 55mm | ||

| Polishing motor speed range | 1500r/min | ||

| Rated power of polishing motor | 1kW | ||

| Feed motor | X-axis | Motor model | HF-SN102J |

| Rated power | 1kW | ||

| Rated torque | 2.7Nm | ||

| Moisture-proof grade | IP67 level | ||

| Z-axis | Motor model | HF-SN102J | |

| Rated power | 1kW | ||

| Rated torque | 2.7Nm | ||

| Moisture-proof grade | IP67 | ||

| Y fast shift speed (radius) | 8000mm/min | ||

| Z-axis fast shift speed | 8000mm/min | ||

| Y-axis stroke | 150mm | ||

| Z-axis stroke | 110mm | ||

| Center height (from the bottom of the bed) | 1100mm | ||

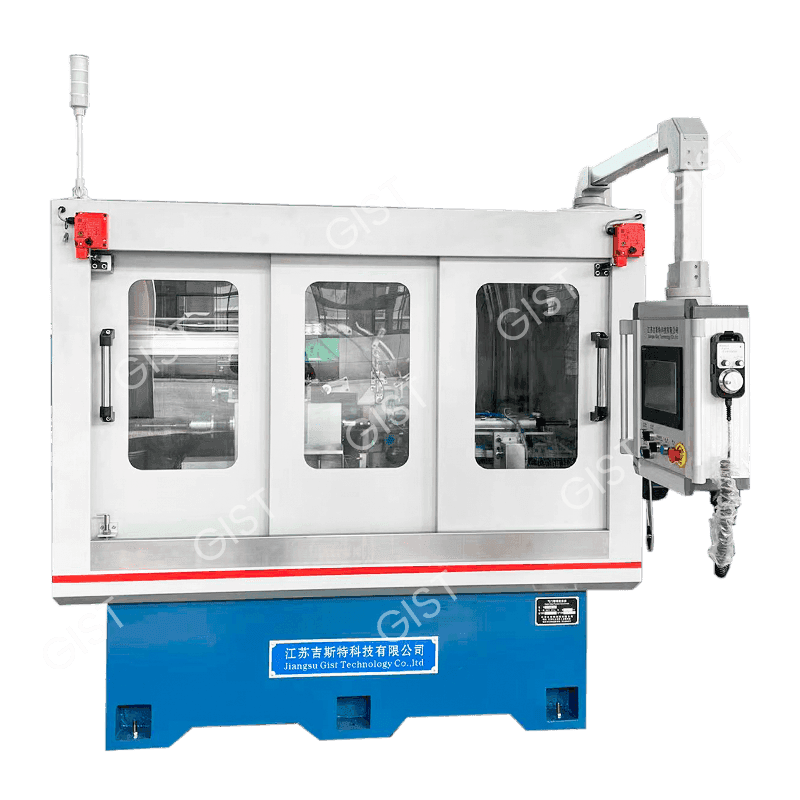

| Machine tool size | Length × width × height | 1500*1550*1700 mm | |

| Total power supply | Voltage | AC380 V | |

| Voltage fluctuation range | -10~+10% | ||

| frequency | 50Hz | ||

| Total power supply capacity | 6KVA | ||

| Total motor capacity | 4KW | ||

| Surface roughness | ≤Ra0.3, continuous processing and measurement 50 pieces | ||

| Processing efficiency | 7S/pin (including automatic loading and unloading) | ||

Main configuration of machine tools

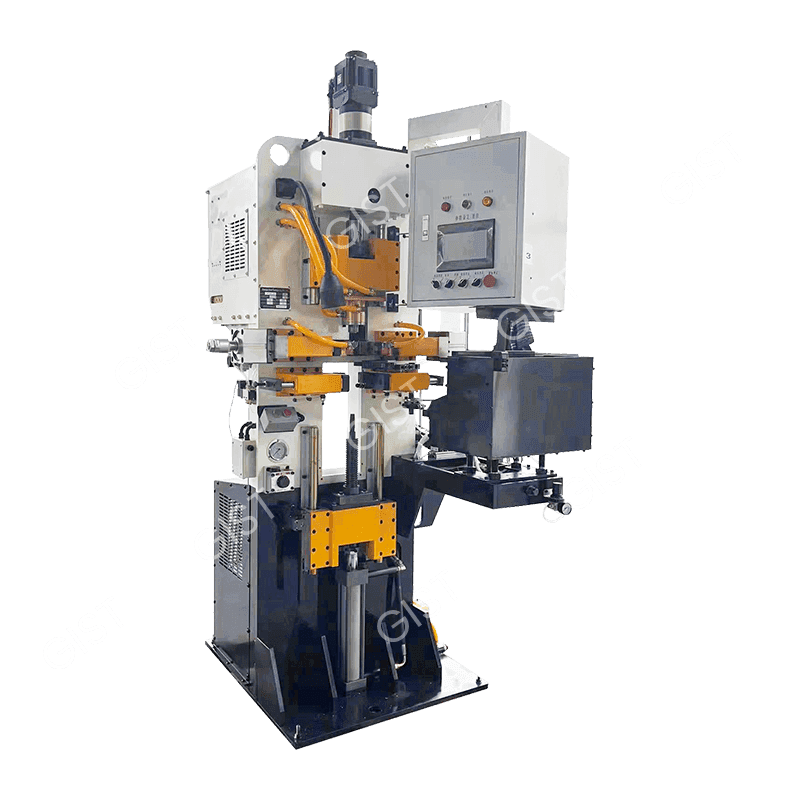

● The machine tool adopts high-strength cast iron casting and molding after casting, and the symmetrical structure is set and thickened to ensure the rigidity, vibration resistance and thermal deformation resistance of the bed, and thicken the relevant parts to improve the rigidity and stability of the machine tool.

● The spindle adopts sealed self-lubricating, which is operated without maintenance for a long time. The automatic lubrication oil pump is automatic lubricating at a fixed point, time and quantity of the feed mechanism. When the automatic oil pump is short of oil or the oil circuit is blocked, the operation will stop automatically, the alarm flashes and reminds you to force refueling.

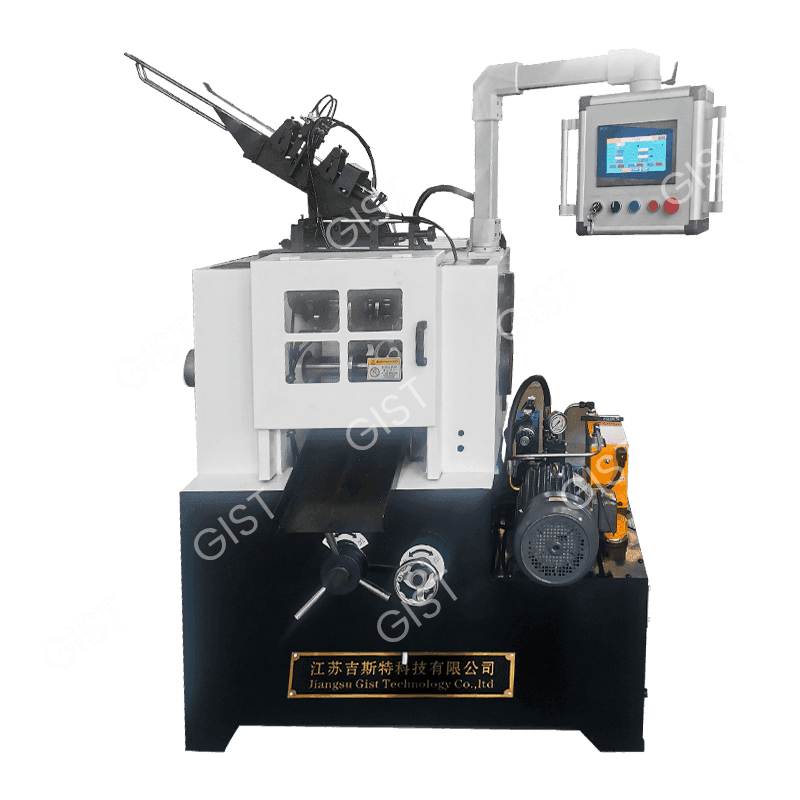

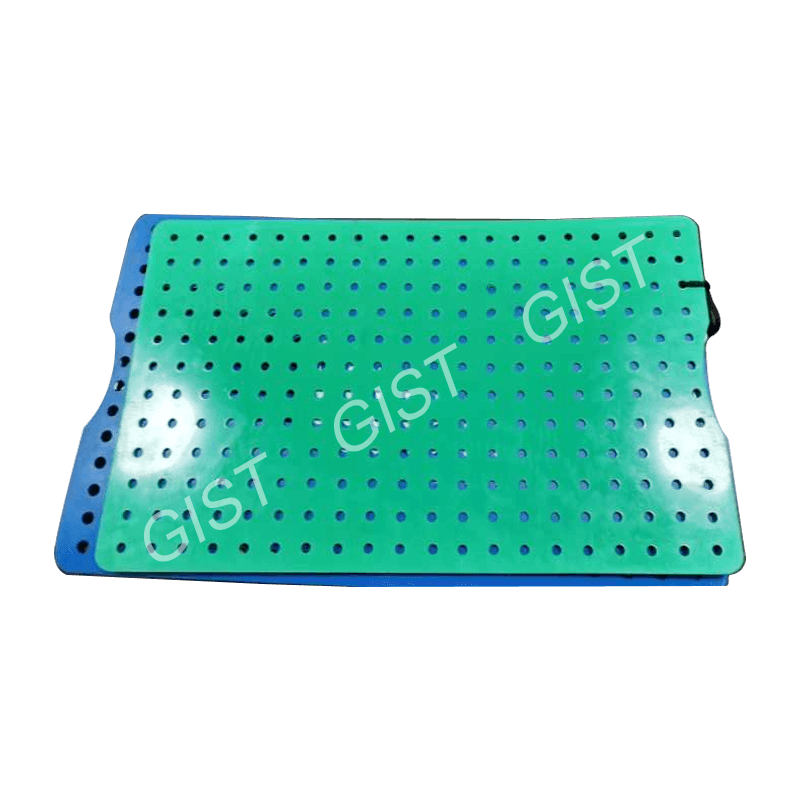

● Pneumatic automatic loading and unloading, and the plate-type material rack structure is convenient for adjusting valves of different models and sizes. Except for loading and unloading, the other actions are carried out simultaneously with grinding. The loading and unloading process should be stable, reliable and smooth.

Functions and uses

It is mainly used for deburring and polishing processes after the engine valve cone surface.

English

English 中文简体

中文简体 русский

русский Español

Español