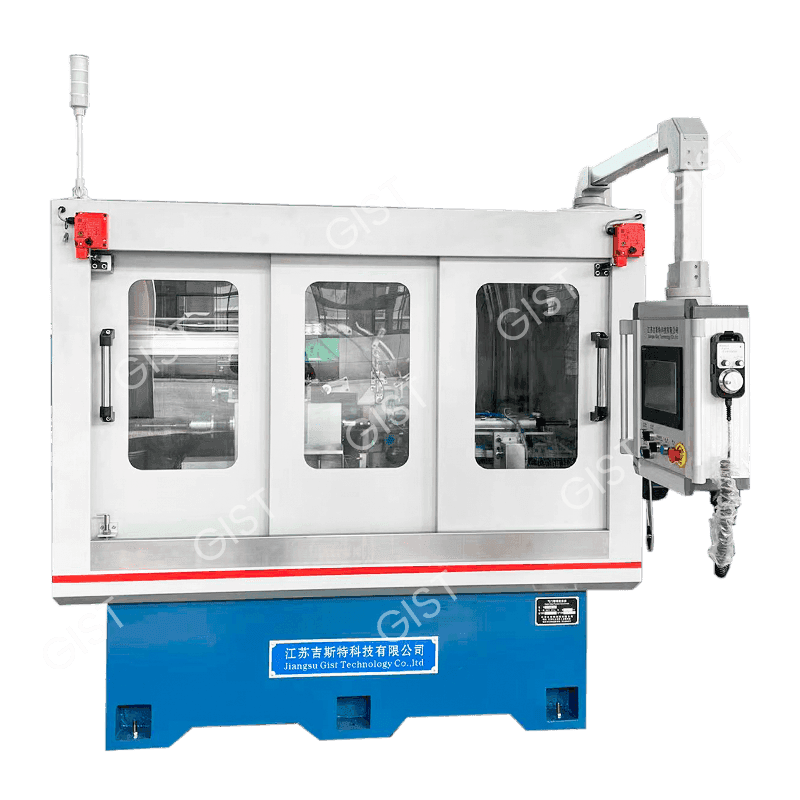

Main parameters of the machine tool

| External dimensions | 8600mm×1800mm×1200mm |

| Effective working size | 6000mm×600mm×100mm |

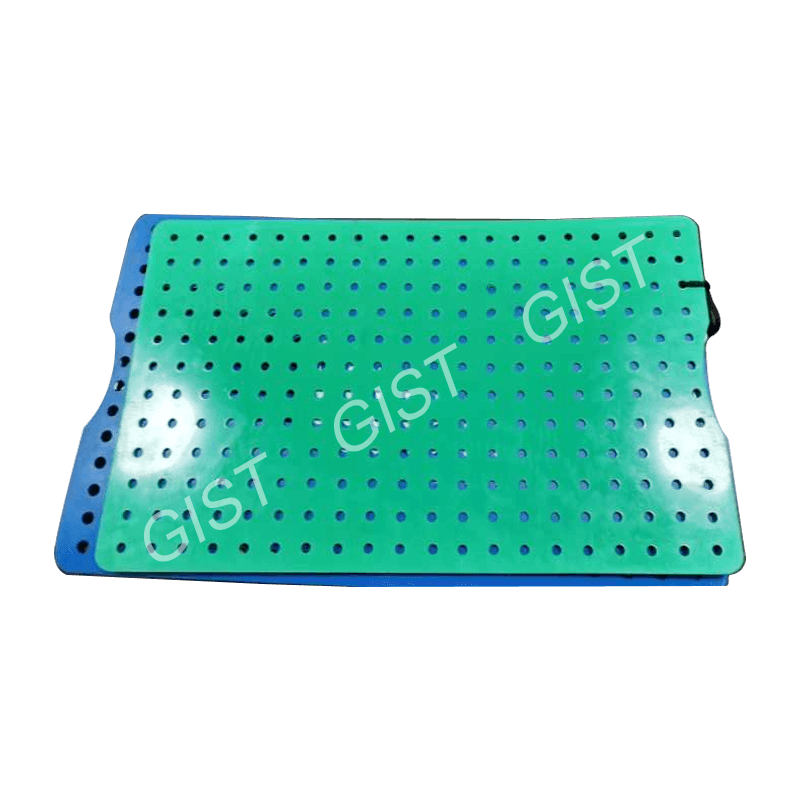

| Network bandwidth | 600mm herringbone folding mesh belt |

| Mesh strip material | SUS309 High temperature stainless steel wire |

| Design temperature | 800℃ |

| Use temperature | 650-750℃ |

| Design temperature zone | Zone 4 PID power control |

| Furnace temperature uniformity | The same temperature zone is ≤5℃ |

| Mesh belt transmission speed | Use PLC to control the inverter (product pass time) for 30~200 minutes inverter speed regulation |

Main configuration of machine tools

● The Japanese Mitsubishi 7-inch human-machine interface is used to control the operation of the equipment, and the equipment parameters and fault alarm information are clearly indicated in the human-machine interface;

● The control cabinet's low-voltage electrical components are all based on the Schneider brand

● Adopt Japanese Izumi relays;

● The equipment has an automatic fault diagnosis system;

Electronic control system configuration

● High temperature furnace control

Each zone uses Japanese Fuji temperature instruments to independently control it, record digital temperature and temperature curves through upper position, display control, and sound-light alarm.

● Alarm control circuit

It has temperature, equipment operation mechanism fault alarm, etc. Alarms can be displayed, stored and printed on the upper computer.

● Program Control

The entire production line uses an intelligent temperature controller for the control of the production line process.

● Software system

It can realize the monitoring, setting, automatic data acquisition and storage functions of industrial computers for temperature, action, and automatic production lines.

Functions and uses

It is mainly used for the heat treatment and tempering process of the engine inlet and exhaust valve.

English

English 中文简体

中文简体 русский

русский Español

Español