Main parameters of the machine tool

| Processing range | Rod diameter | Φ4mm~Φ12mm |

| Disk diameter | Φ20mm~Φ55mm | |

| Overall length | 60mm~220mm | |

| Processing accuracy | Disk plane to tapered surface size | ±0.05mm |

| Rough arc | Ra1.2 | |

| Diameter tolerance | ±0.03mm | |

| Processing efficiency | Include loading and unloading | <7S/support (referenced by rod diameter 5mm) |

| Tools | Forming blade | |

Main configuration of machine tools

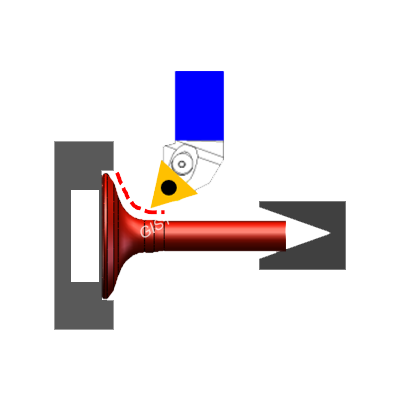

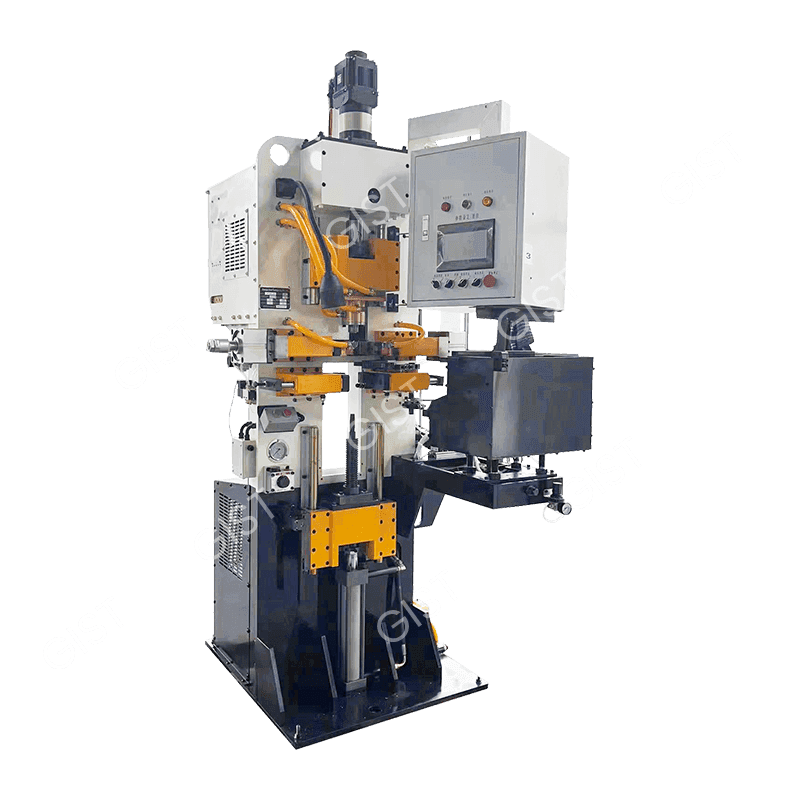

● The machine tool bed is 45° installed, the overall bed seat, the X/Z guide rail is a high-rigid linear rolling guide rail pair, the ball screw is placed between the two guide rails, the transmission has no tilt recurrence torque, the machine tool runs smoothly and has good stability, the guide rail screw is automatically lubricated, which can extend the service life of linear guide rails and ball screws and ensure high-precision feed.

● A special elastic fixture for valve clamping of machine tools can be equipped with an automatic valve loading and unloading robot, and can also be used with this machine tool; the parts are automatically transported into the line, and the valve is automatically connected to the automatic valve connection processing, with high efficiency, fast pace, low management cost, and suitable for large-scale valve production machine tools.

● This machine tool adopts fully enclosed protection to ensure the safety of operators and equipment, and is also protected from oil and waterproof, making the factory environment clean.

● The machine tool has a beautiful appearance, easy maintenance, and good operators.

Functions and uses

It is mainly used for arc turning of engine inlet and exhaust valves, precision turning of various pipe fittings, various shafts and molds.

English

English 中文简体

中文简体 русский

русский Español

Español