CNC Disk End Lathe

Cat:CNC Lathe

Category: CNC lathe Product Overview: The company has passed the certification of various systems such as ISO9001:2015 quality management system, ...

More01

The origin of the centerless grinder

The origin of the centerless grinder can be traced back to the early 20th century. At that time, automobiles developed rapidly, and more than 20 automobile companies such as Mercedes-Benz, Ford, and General Motors were established one after another. The automobile production organizational form entered standardization and assembly line production. The centerless grinder was born under the demand of the automobile industry for high production volume of precision parts.

Automobile production workshop in the early 20th century

In 1921, Cincinnati Milling Machine Company accepted a grinder order from Ford Motor Company, manufactured ten centerless grinders for the on time, and delivered them to Ford on February 17, 1922.

Cincinnati's centerless grinder delivered to Ford

With the birth of the centerless grinder, the dimensional accuracy and roundness of the parts have been directly increased by one quarter, and the production time has dropped to one tenth of the original. This centrifugal grinding technology not only enables mass production, but also enables the manufacture of interchangeable parts.

02

Development of centerless grinding machines in our country

In my country, centerless grinders started late, but developed relatively quickly, and have experienced three major stages: imitation production, self-design and modern design.

1. Imitation production stage

1954-1960 was the imitation stage. In 1954, Wuxi Machine Tool Factory imitated the ordinary centerless grinder M2075. In 1957, the wide sand centerless grinder M1075K was imitated.

my country's centerless grinder (Picture source: Wuxi Machine Tool Factory official website)

2. Self-design stage - Self-development of my country's centerless grinder M1025

In October 1956, Wuxi Machine Tool Factory began to design the M1025 grinder under the guidance of Soviet experts. Through the joint efforts of technicians and old workers, various technical difficulties were overcome. In March 1958, the new product was assembled and the appraisal was passed.

This is the grinder designed by Wuxi Machine Tool Factory, and it is also the self-developed centerless grinder in my country. The successful development of this centerless grinder has accumulated a lot of valuable experience for the subsequent research and development of our centerless grinder.

From 1961 to 1970, Wuxi Machine Tool Factory special centerless grinding machines for processing gas valves, ball pins, cross shafts, steel pipes, motor shafts, etc. have been designed in China. These mark the maturity of self-designs of centerless grinders in our country. During this period, Wuxi Machine Tool Factory, Xianfeng Machine Tool Factory, Benxi Second Machine Tool Factory, Changchun Machine Tool Factory and other manufacturers successively produced a series of ordinary centerless grinding machines.

3. Modern design stage

With the development of science and technology, since the early 1980s, centerless grinders have entered the modern design stage. my country has not only developed a new generation of high-precision grinders and high-speed centerless grinders, but also applied modular design, static and dynamic finite element design, computer-aided design and optimization design to the design of centerless grinders.

03

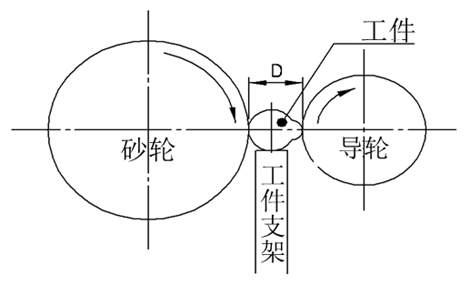

Working principle and method of centerless grinder. As the name suggests, the centerless grinder is a type of grinder that does not need to clamp the center of the workpiece to grind. It is mainly composed of three mechanisms: grinding grinding wheel, guide wheel (adjustment wheel) and workpiece bracket (pallet). The function of the grinding wheel is to remove the surface from the grinding and generate the desired degree of light; the function of the guide wheel is to control the rotation speed of the grinding; the workpiece bracket is used to support the grinding during grinding.

According to the workpiece feed method, there are three centerless grinding methods:

Cross-direction feeding method: suitable for grinding of multi-diameter or special-shaped workpieces. Through-feeding method: It has high production efficiency for grinding needle rollers, cylindrical rollers, and tapered rollers. Tangential feeding method: Ability to grind a special-shaped workpiece, such as a spherical roller.

04

Advantages and disadvantages of centerless grinding and cylindrical grinding

We know that among all grinders, cylindrical grinders are the widely used machine tools, and can process various cylindrical conical outer surfaces and shoulder end surface grinders. So when processing a workpiece, should we choose centerless grinding or cylindrical grinding? This requires understanding their characteristics and advantages and disadvantages.

We have just introduced the working principle of the centerless grinder, and the following are its characteristics.

1. Continuous processing, no need to retract the tool, short time for clamping workpieces, and high productivity.

2. The bracket and guide wheel positioning mechanism have better support rigidity than ordinary cylindrical grinders and the central frame mechanism, and can be larger in cutting volume, which is conducive to the processing of slender shaft workpieces, making it easy to achieve high-speed grinding and strong grinding.

3. The workpiece of the centerless outer cylindrical grinder is positioned on the positioning mechanism by the outer cylindrical grinder. The grinding amount is the allowance in the diameter of the workpiece. Therefore, the wear of the grinding wheel, the compensation of the feed mechanism and the repeated positioning accuracy error of the cutting mechanism on the diameter and dimensional accuracy of the part is only half that of the ordinary outer cylindrical grinder. There is no need to drill a central hole, and it is easy to achieve automatic loading and unloading.

4. The wide grinding wheel centerless grinder passes through the mechanism, which can increase the processing allowance each time. When cutting into the grinding, complex surfaces can be grinded in sequence or multiple grinding wheels, which has high productivity and a wide range of application.

Compared with centerless outer cylindrical grinders, the following characteristics are:

1. In terms of grinding efficiency, cylindrical grinding is far worse than centerless grinding, so the production cost is relatively high.

2. However, compared with centrifugal grinding, the advantages of external cylindrical grinding are also very obvious.The cylindrical error generated during the lathe processing in the front of the roller core can be corrected; second, the step shaft can be grinded; if it is a CNC external cylindrical grinder, it can also be ground in medium and high or arc surfaces.

3. In terms of overall cylindrical accuracy, cylindrical grinding is generally better than centrifugal grinding.

05

Centerless grinder processing locomotive diesel engine valve rod

After introducing the advantages and disadvantages of centerless grinding and cylindrical grinding, let’s take a look at a practical application case.

Locomotive diesel engine valve

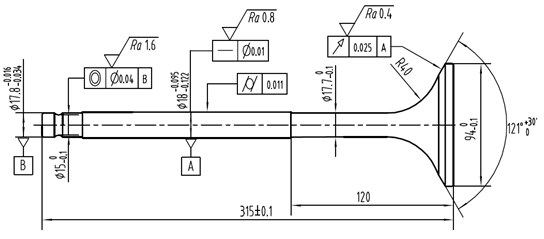

Valves are an important part of the operation of diesel engines. In the 1970s and mid-1980s, the company adopted the traditional cylindrical grinding process (both end positioning method), but since the valve rod length-to-diameter ratio is greater than 10 (see the figure below).

DF11 locomotive diesel engine valve

The traditional cylindrical grinding method greatly reduces the rigidity of the grinding process system. At the same time, there is generally unevenness in the size of the valve rod after grinding, especially the problems of drumming defects in the rod and low processing efficiency have not been well solved.

In the mid-to-late 1980s, the company introduced Japanese centerless grinding machines. The overall route of the valve processing technology was redesigned around the rod by centerless grinding method (cutting grinding method). In the subsequent processing process, the advantage of centerless grinding process of the valve rod was clearly reflected, mainly manifested in: good dimensional tolerance consistency (within 0.02mm), good surface roughness uniformity (any surface roughness of the rod part is within Ra0.35), and centerless grinding can achieve high shape and position tolerance requirements.

The company learned from decades of experience in mass manufacturing valves that the valve rod part adopts centerless grinding is the efficient and convenient batch processing method. With the continuous development of the valve product market, the company's two valve production lines currently have multiple centerless grinding machines (Microsa, Japan, and Guangyang, Japan) for centerless grinding valve rod part. The equipment processing specifications can undertake various types of medium-speed diesel engine marine valves, and can assist customers in the research and development of high cost-effective diesel engine valves.

centerless grinder

06

summary

Centerless grinding is a high-production-efficient precision machining method in the current mechanical processing methods. This grinding method can enable the workpiece to obtain good surface processing quality, high processing accuracy and high processing efficiency. It is widely used in the processing of pins, slender rods and pipes with long diameters, and is widely used in the field of bearing manufacturing.

In recent years, my country's machine tool factories that produce centerless grinders have kept pace with the development of the times and strived to improve the performance of centerless grinders. Although there is still a certain gap with foreign advanced centerless grinders in the application of new materials and the research and development of new technologies, my country's centerless grinder manufacturers face difficulties and strive to overcome technical difficulties, which has led to my country's centerless grinder technology developing towards high-speed, high-precision, high-efficiency, environmental protection and intelligence.