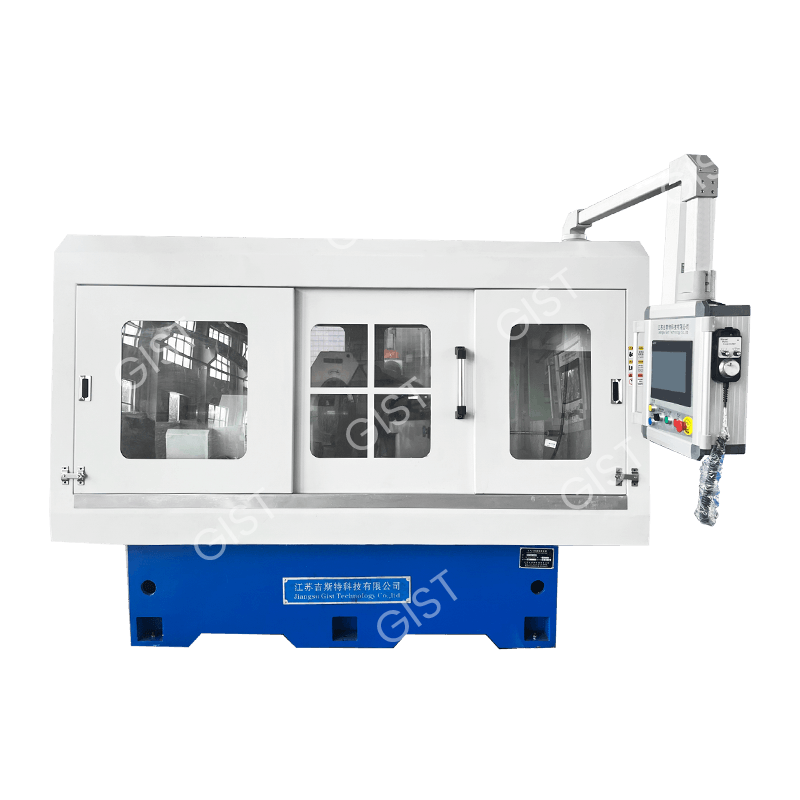

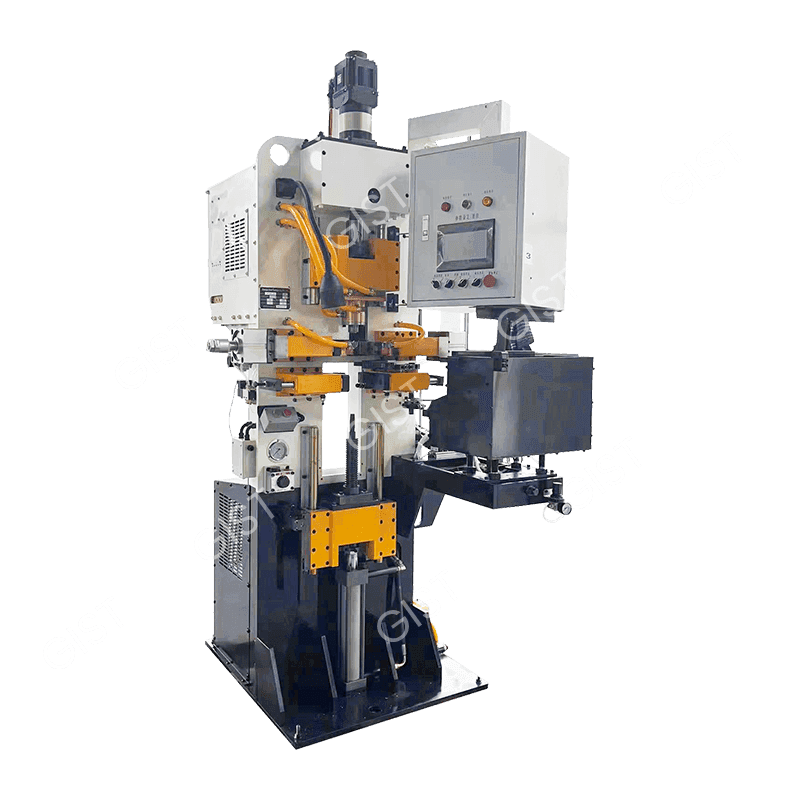

Jiangsu Gist Technology Co.,ltd (formerly Dongtai Weifeng Machinery Factory was born in 2012) The new company was established in April 2020. The company's address is No. 1, Industrial Concentration Zone, Wulie Town, Dongtai City, covering an area of 22 mu, the factory building area is more than 11,000 square meters, and the total investment is 100 million yuan. The groundbreaking construction started in early 2021 and completed the construction in early 2022. The company is a manufacturer of complete machine automation equipment that integrates development, design, production, manufacturing, sales and after-sales service. The company has a group of highly technical design teams and high-quality front-line skilled employees. According to customer requirements, various high-precision and intelligent high-quality manufacturing equipment can be carefully customized for customers.

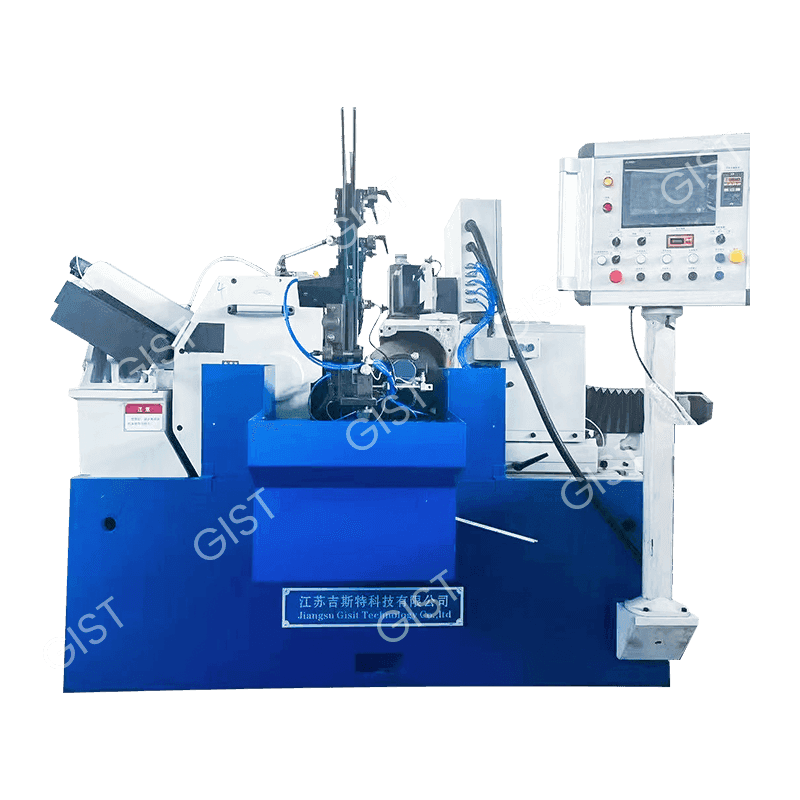

As a professional China

Marine Cone Grinding Machine Manufacturers and

Marine Cone Grinding Machine Factory, The high-end intelligent automation equipment produced by our company is used in the fields of core engine components such as locomotives, generator sets, mining machinery, commercial vehicles, ships, etc. It has maintained long-term cooperation with foreign-funded enterprises such as the engine parts manufacturing company, Germany MAHLE, the power management company, the United States EATON, and other foreign-funded enterprises, and has entered their global procurement system. The company has the right to import and export independently, and has exported equipment to more than 20 countries and regions such as Germany, Japan, Türkiye, and Iran in recent years. It has established a close partnership with major domestic engine valve manufacturers: Chongqing Sanai Hailing Industrial Co., Ltd., Jinan Ward Auto Parts Co., Ltd., Dengyun Co., Ltd.-Huaiji Lunar Valve Co., Ltd., etc.

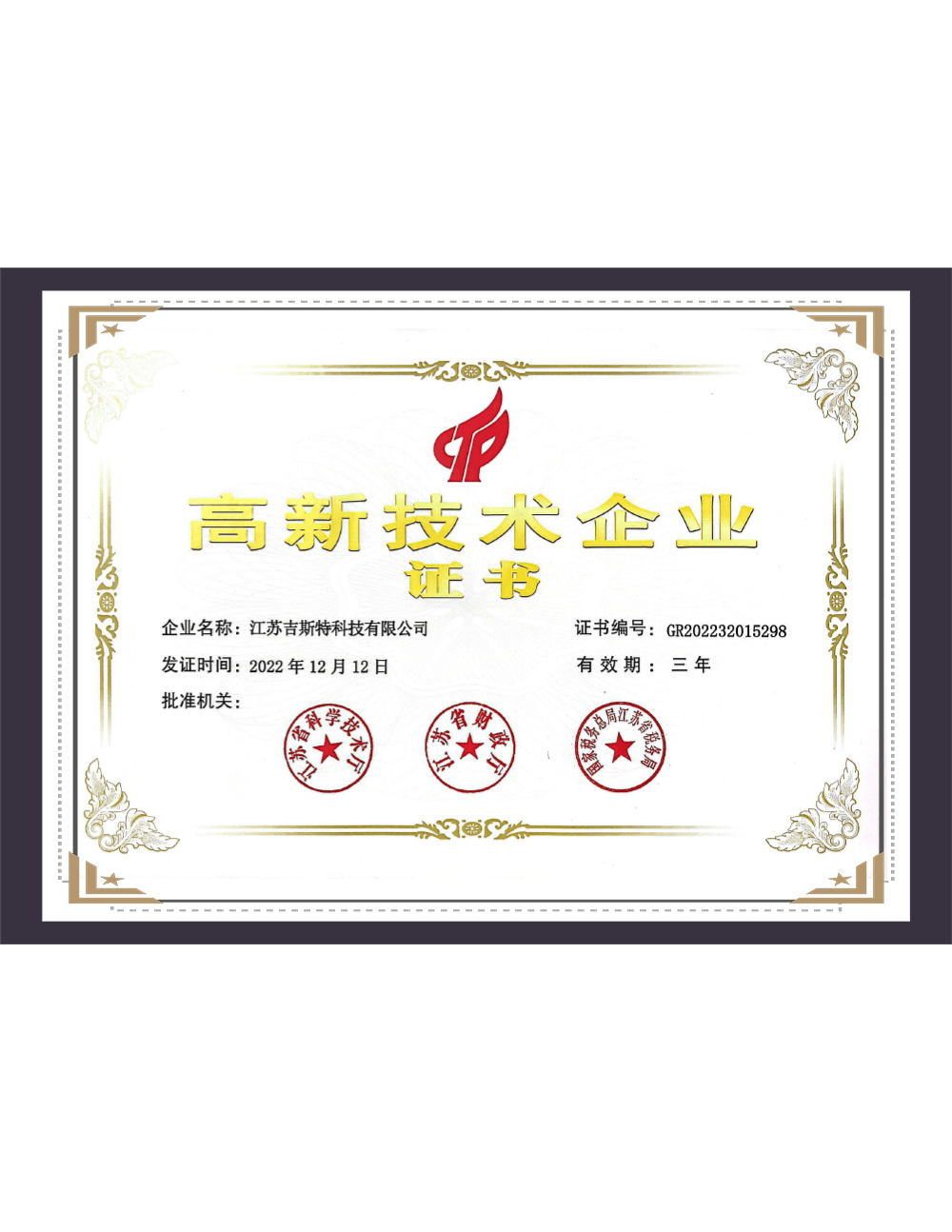

The company has more than 10 invention patents and more than 100 utility models. It was awarded a national high-tech enterprise in 2022 and a specialized and specialized enterprise in 2024.

The company has passed the certification of various systems such as ISO9001:2015 quality management system, ISO14001:2015 environmental management system, ISO45001:2018 occupational health and safety management system, and has implemented various system management requirements, and has continuously innovated and improved to meet the all-round needs of customers. Adhering to the principles of people-oriented, win-win cooperation and customer , we warmly welcome domestic and foreign customers to visit our company for guidance!

English

English 中文简体

中文简体 русский

русский Español

Español